Sugar cubes

As a wholesaler, August Töpfer & Co. offers classic sugar cubes made from refined sugar as well as speciality cubes from a factory in Mauritius. The factory specialises in the production of irregular cane sugar cubes.

What are sugar cubes?

Sugar cubes – also known as lump sugar – is characterised by its often cuboid shape and is made from different types of sugar. The most common variety are sugar cubes made from white granulated sugar or refined sugar. They have a particularly high sugar content of over 99 percent and are distinguished by a pure white colour and sparkling crystals. Alternatively, brown beet and cane sugar are also used for the production of sugar cubes. Moreover, the product is available in special shapes such as hearts or clove leaves. Sugar shaped like playing card suits even exists.

At wholesaler August Töpfer & Co., you can order a speciality from our factory in Mauritius in addition to classic sugar cubes. There we produce irregular lumps made from brown cane sugar. The raw material gives the product a characteristic flavour similar to caramel. The product is available in both retail and bulk packaging.

The history of sugar cubes

A type of shaped and dried sugar was already common before the 19th century. Until then, conical-shaped sugar loaves were available. They could be obtained up to a size of 1.5 metres and with a weight of up to 150 kilograms. To break these into smaller pieces, consumers needed their own sugar hammer. This process was cumbersome and tedious.

Juliane Rad injured herself in 1841 while trying to break up a piece of sugar. She then asked her husband to come up with a safer method to enjoy sugar. As the director of a sugar refinery in Austria, Jacob Christoph Rad had the ideal opportunity to develop a new type of sugar. After three months, he presented his wife with 350 pieces of cubed sugar made from sugarbeet.

In 1843, Mr Rad obtained an imperial-royal patent for this practical alternative to sugar loaves, limited to five years. To produce the sugar cubes, the inventor developed a model made from metal strips, resembling modern ice cube containers. The brass plates contained 400 holes and enabled the drying of sugar cubes. The new product became highly popular and was sold under the names “tea sugar” and “Viennese sugar cubes”. The inventor’s company soon produced more than 1,000 kilograms of the product every day.

Sugar cubes also quickly spread beyond the borders of Austria. The inventor sold his patent to Bavaria, Switzerland and England, among other places. But sharing the production technique left Jacob Christoph Rad by the wayside. The inventor closed down his company in 1852. Other countries developed the invention further and were able to break and cut the sugar mechanically, for example. In the mid-20th century, a rotation machine was invented that has shaped the industrial production of sugar cubes to this day. The method originates from a French mechanical engineer who pressed the tempered sugar into the desired shape.

Until well into the 1990s, sugar cubes were typically packed in twos, which were served in cafés, restaurants and other catering establishments with coffee. Over time, pouches and sachets largely replaced sugar cubes here. However, this type of sugar is still common. Wholesale sugar cubes are ideal for certain applications due to their shape and standard size. Indeed, sugar cubes are often used as a unit of measurement to illustrate how much sugar is contained in food. Sugar cubes make it easy to visualise the sugar content. For instance, 100 grams of a popular milk chocolate bar contain around 19 sugar cubes, made from an average of three grams of sugar in Germany.

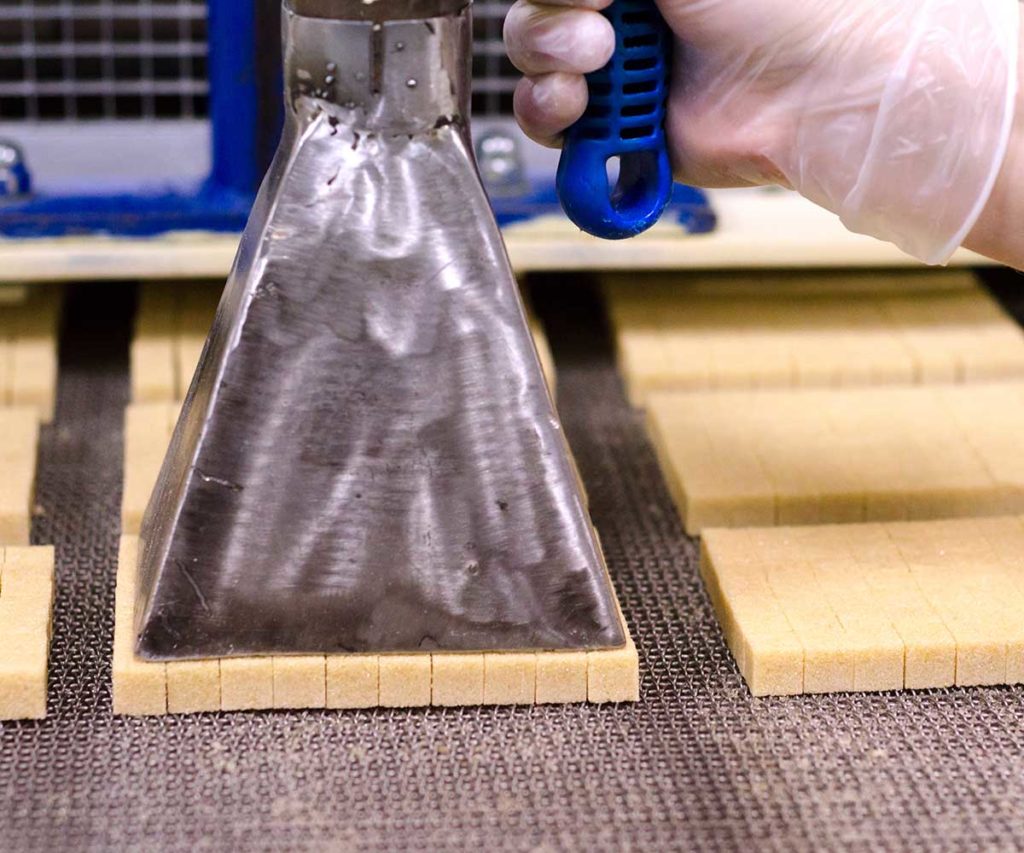

Production of sugar cubes

The production of sugar cubes starts by dampening the chosen sugar. This makes the individual sugar crystals sticky and allows them to form stable bonds. These bonds are primarily found on the surface of the cubes, while the internal connections are somewhat weaker. Sugar cubes are therefore easy to crush. In the next step, the sugar is pressed into the desired shape. Typically, the mass is pressed in plates and strips and then cut into cubes. Cast cubes are made by filling and setting in moulds and they dissolve more easily in drinks. The product is then dried so that it retains the desired shape. To ensure a long shelf life and prevent the clumping of individual cubes, some producers add a separating agent during the production process. Unusable pieces are left over in the production of sugar cubes. These are further processed and used for the production of coarse granulated sugar.

The use of sugar cubes

The traditional use of sugar cubes is still common to this day. This form of sugar is ideal for sweetening hot beverages like tea or coffee. The sugar dissolves quickly due to the high temperature. For use in dishes and food, wholesale sugar cubes are also useful as a dosed sweetener, for example in sauces or chutneys.

Sugar cubes are a classic, popular treat for horses. The teeth of the animals continuously regrow, which means cavities are less critical. However, attention should be paid to an appropriate energy intake for the animals due to the high calorie content. Meanwhile, a number of alternatives to sugar cubes for horses can be found on the market. It is important to ensure that the animal feed is free from molasses. This promotes the development of plaque, which is very difficult to remove. Fresh fruit and vegetables are also great as treats for horses and they are suitable alternatives to sugar cubes.

Unser Würfelzucker ist zertifiziert:

Sugar cubes from wholesaler August Töpfer & Co.

At August Töpfer & Co., you can buy sugar cubes from a Hamburg-based wholesaler that attaches great importance to tradition and quality. Irregular cane sugar lumps are a highlight in our sugar cube range. This product is manufactured by our specialised factory in Mauritius, which produces small packaging in customer retail units (500, 750 and 1000 grams). Our wholesale range also encompasses Organic sugar cubes. Besides sugar pressed into shape, we offer further sugar products including white sugar or Industrial sugar, Raw cane sugar, Demeter organic sugaror lactose.

Our customers include leading retailers and discounters as well as the confectionery industry throughout Europe. For all our products, we source raw materials directly from selected producers in the countries of origin with whom we maintain close contact. Long-term cooperation enables us to offer high quality at fair prices.